Mastering Piping and Instrumentation Systems

- Jul 9, 2025

- 5 min read

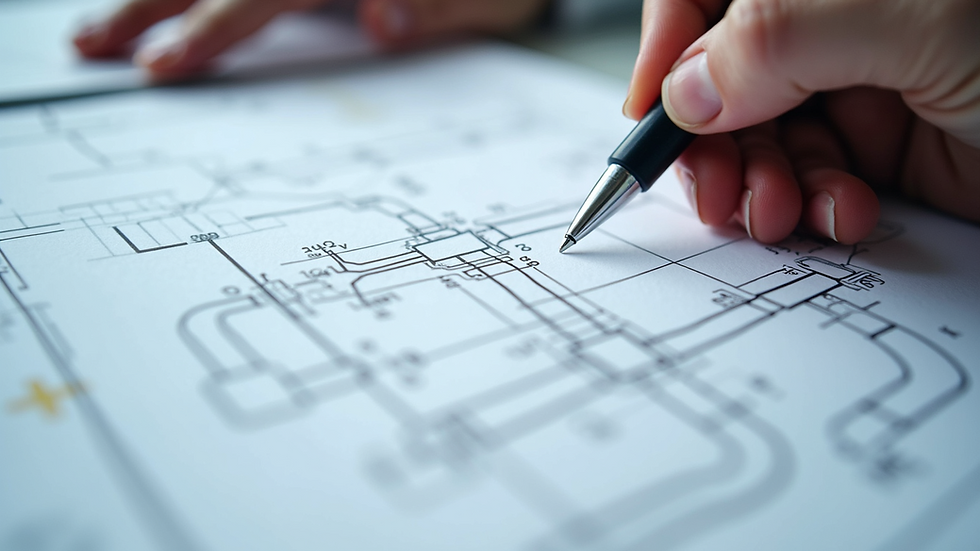

Piping and instrumentation systems are crucial components in various engineering fields, ensuring that liquids and gases flow efficiently and safely. Whether you're in the oil and gas industry, chemical production, or even HVAC systems, understanding these systems can significantly enhance your operational efficiency. This blog post will delve deep into piping instrumentation essentials, looking at their functions, theories, and how they are represented in technical drawings.

Piping Instrumentation Essentials

The classification of piping systems can seem daunting at first, but once you grasp the basics, you'll see how they all fit together. Piping systems transport fluids from one point to another, whether that's raw materials, finished products, or waste. Instrumentation involves devices used to measure and control these processes.

In its essence, piping systems consist of pipes, valves, fittings, and occasionally pumps or compressors. Each of these components plays a role in maintaining the integrity and flow of the system. The design principles behind piping systems often consider pressure, temperature, and fluid type, all of which influence material selection and system layout.

For practical understanding, consider a water treatment facility. Here, pipes transport water through different phases of treatment. Instruments like flow meters and pressure gauges monitor the process, ensuring that everything is operating as intended. The combination of these elements is what makes piping and instrumentation systems effective and essential.

Understanding Flow and Pressure Dynamics

Flow dynamics is the study of fluid motion. In piping systems, control over flow and pressure is vital for safety and efficiency. Understanding basic fluid mechanics can empower operators to anticipate and manage various scenarios.

Fluid flow can be classified as laminar or turbulent. Laminar flow occurs when fluid moves in parallel layers, while turbulent flow is chaotic and characterized by eddies and swirls. Each type of flow has implications for pipe sizing, potential blockages, and the efficiency of pumping systems.

For example, if an oil pipeline experiences turbulent flow, it may require more energy to pump the oil, increasing operational costs. Conversely, managing laminar flow can lead to energy savings and improved flow management.

Additionally, pressure is another critical factor. High pressure in pipes can lead to failures and leaks, potentially causing dangerous situations. Regular monitoring with gauges and control systems ensures that pressures stay within specified ranges.

What is Shown on Piping and Instrumentation Drawings?

Piping and instrumentation drawings (P&IDs) are complex visual representations of the piping systems within a facility. They serve as essential blueprints, depicting not only the layout of pipes but also the instruments used to control various processes.

A basic P&ID includes symbols that represent the piping, valves, and instruments. For instance, a solid line often represents a pipe, while a dashed line may indicate the physical location of a valve. Symbols used on these drawings must comply with specific industry standards to ensure clarity and uniformity.

P&IDs also provide important information such as flow direction, control loops, and interconnections between different components. They help engineers, operators, and maintenance personnel quickly understand system operations and troubleshoot issues.

For example, in a chemical plant, a P&ID may illustrate the connections between reactors, separators, and storage tanks, along with the instrumentation that monitors temperature and pressure at each stage.

The Importance of Regular Maintenance and Upgrades

Maintenance of piping and instrumentation systems is crucial for ensuring operational safety and reliability. Regular inspections can prevent leaks or failures that could disrupt production or cause hazardous situations. Here’s how you can manage maintenance effectively:

Scheduled Inspections: Create a routine inspection schedule based on the manufacturer’s recommendations and industry standards. Regular checks can identify issues like corrosion, blockages, or instrumentation failures.

Upgrade Aging Systems: Older piping systems may not meet modern standards. Upgrades not only enhance safety but can also lead to enhanced efficiency and reduced costs over time.

Use of Sensors: Incorporate modern technology into your maintenance routines. Real-time monitoring sensors can alert operators to abnormal conditions before they escalate into serious problems.

Training and Protocols: Ensure all staff are trained in maintenance protocols and understand how to interpret readings from instrumentation systems. This knowledge can significantly enhance the workplace's safety culture.

Establishing a continuous improvement program tied to piping and instrumentation maintenance can lead to long-term operational benefits, including increased efficiency and reduced downtime.

Future Trends in Piping and Instrumentation Systems

The future of piping and instrumentation is evolving rapidly with advancements in technology. Innovations are paving the way for smarter systems, making operations safer and more efficient. Here are a few trends to watch:

Digital Twin Technology: Creating digital twins of piping systems allows for simulations that predict how systems will respond under different conditions. This can aid in system design and troubleshooting.

IoT Integration: The Internet of Things (IoT) is making its mark in the industry. Sensors connected to the internet can provide real-time data, leading to better decision-making and enhanced safety measures.

AI and Predictive Maintenance: Artificial intelligence is being implemented to analyze data and predict maintenance needs before failures occur. This proactive approach can save both time and resources.

Sustainable Practices: As the world focuses on sustainability, there’s a push towards more environmentally friendly materials and practices in piping systems. This includes using recycled materials and optimizing transportation routes to minimize energy consumption.

By staying ahead of these trends, professionals can enhance their understanding of piping and instrumentation and adapt to changing industry needs.

Practical Steps for Mastery

To master piping and instrumentation systems, consider the following actionable steps:

Educational Courses: Enroll in specialized courses that focus on piping design and instrumentation. Many universities and technical schools offer programs tailored to these topics.

Hands-on Experience: Gain practical experience through internships or training programs. Working in real-world settings can help solidify your understanding of theoretical concepts.

Networking: Join industry associations or online forums focused on piping and instrumentation. Networking offers insights and mentorship opportunities from experienced professionals.

Stay Updated: Regularly read industry publications and blogs such as Flowio Engineering. Staying informed about new technologies, regulations, and best practices is crucial.

Through continual learning and practical application, professionals can not only master piping and instrumentation systems but also contribute to their field meaningfully.

By enhancing your understanding of piping instrumentation essentials, you can elevate your expertise and play a vital role in ensuring the efficiency and safety of engineering systems across various industries. Whether you are an aspiring engineer, technician, or an industry veteran, there’s always more to learn and apply to your work.

Comments